Project Portfolio

Product Design and Prototyping

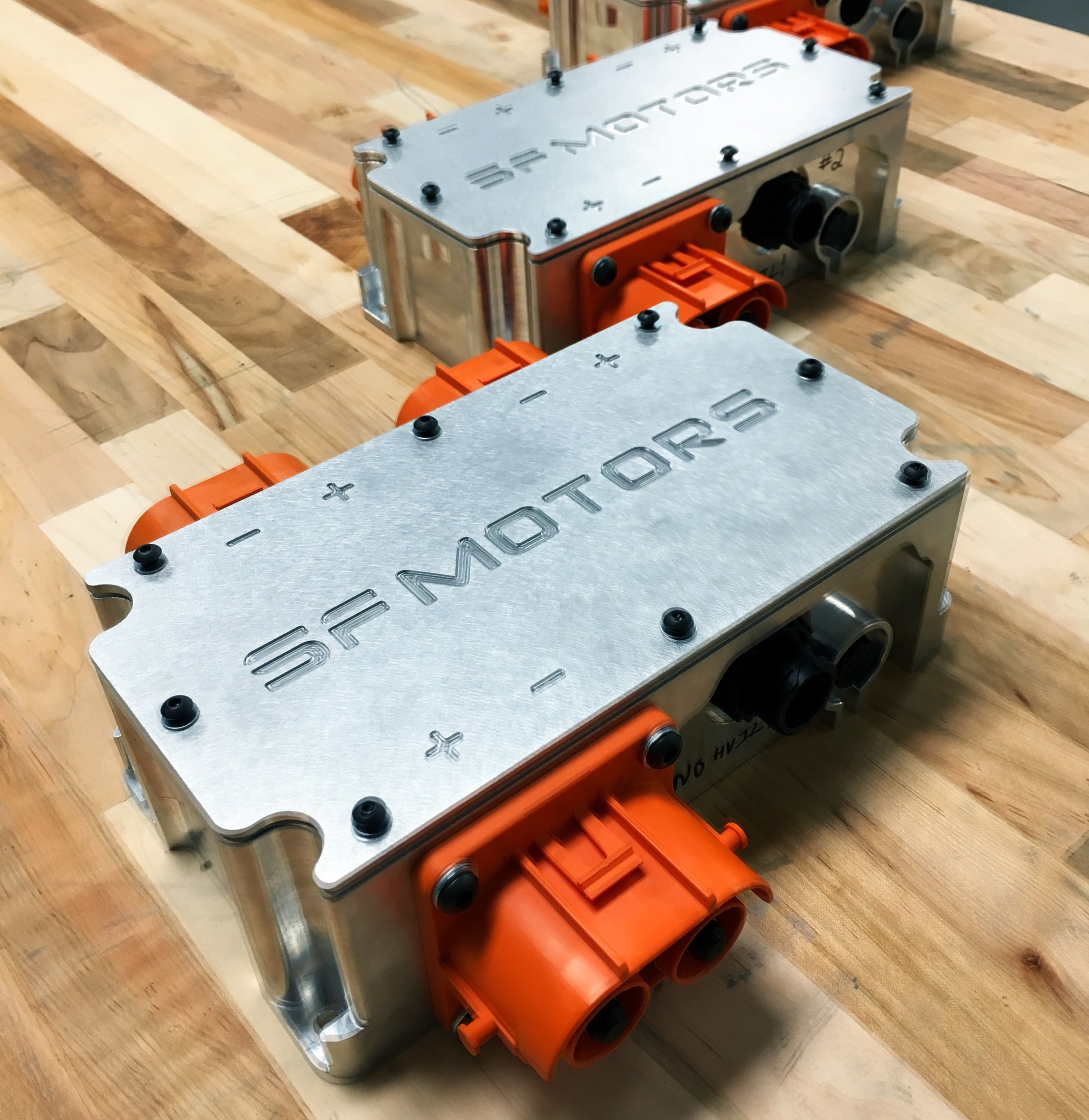

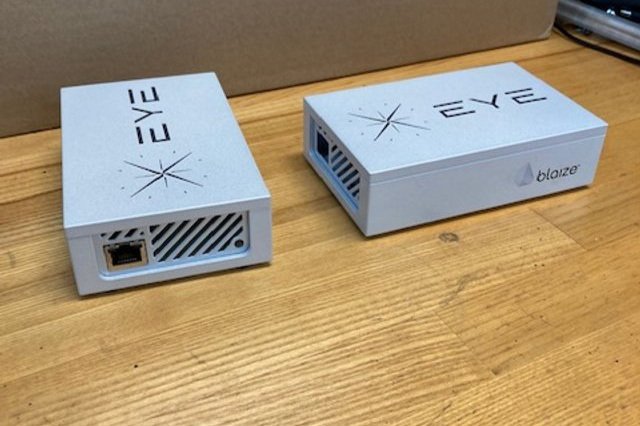

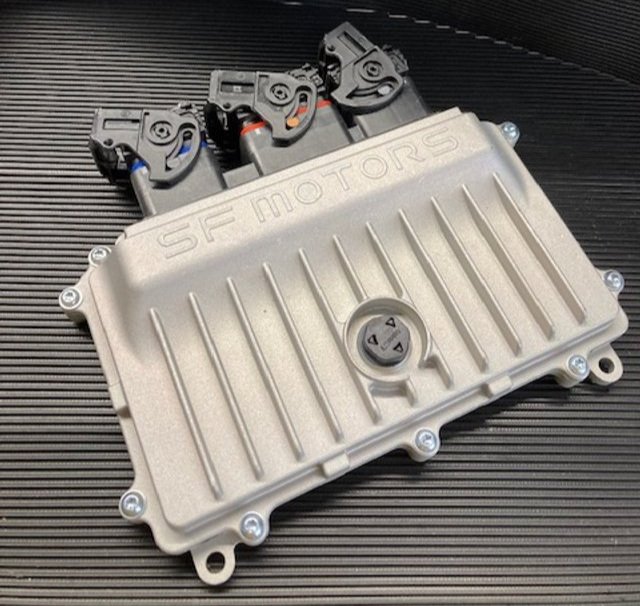

Electronics, computing, and electric vehicle manufacturers: These products include EV junction boxes, communications devices, and add-in cards for AI computing. All were designed in close collaboration with clients’ electrical engineers, PCB designers, and product leadership. Design scope in some cases included custom copper bus bars, safety switches, electrical insulators, and/or LED lighting. Some were one-off conceptual marketing pieces, or produced at low volumes for lab testing. For others, Darby Prototype supported the entire product development process, leading to high-volume production with Asian manufacturing partners. Typical Role: Mechanical design, fabrication management, and final assembly.

Medium-scale Energy and Thermal Systems

Combined Heat and Power System “BBEST”: 100 kW Combined Heat and Power System with a micro gas turbine and Altex Technologies' patented burner design. Role: Program Manager at Altex Technologies.

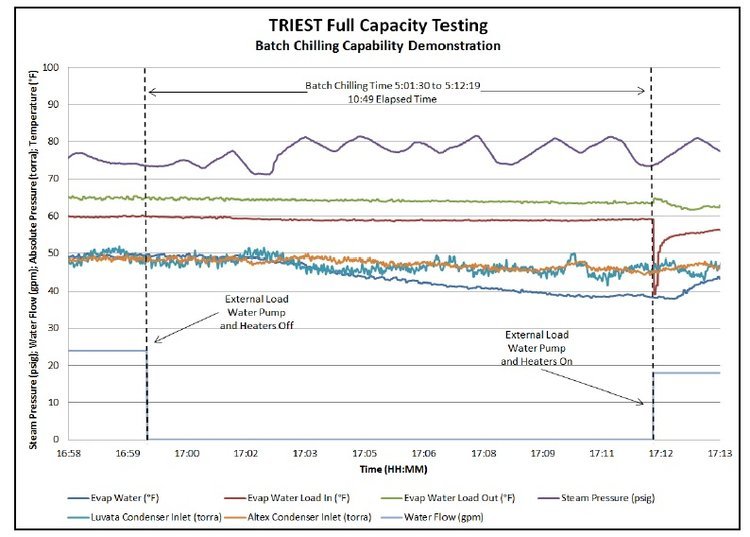

Vacuum-based Process Chiller “TriEST”: A seven ton refrigerant-free cooling system that utilized waste steam energy to chill water. Role: Program Manager at Altex Technologies

Agricultural Drier: Hot air drier for CBD hemp in Oregon. Capable of drying 1000 lbs of crop to the required moisture content in <12 hrs. Role: Process and mechanical design, commissioning support.

Liquid Fuels Reformer “STAR”: A compact chemical processor to convert liquid fuels into hydrogen-rich gas streams for fuel cell vehicles. Role: Lead Mechanical Design Engineer at Nuvera Fuel Cells.

Prototype Design & Fabrication, early stage products

Early stage inventors and companies often require proof-of-concept or “minimum viable product” hardware. Unlike large product development firms, Darby Prototype is willing to work on small-budget projects to help inventors accelerate early growth.

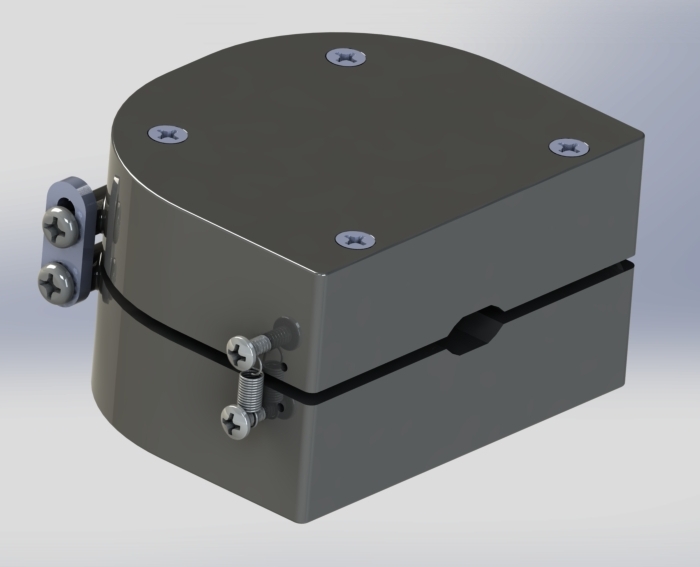

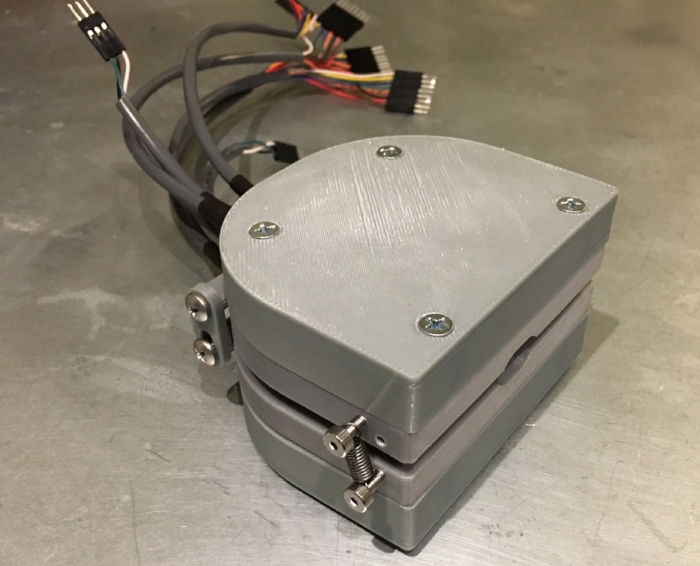

Device Prototype #1 : Medical device with eighteen sensors and an interface for off-board microprocessor.

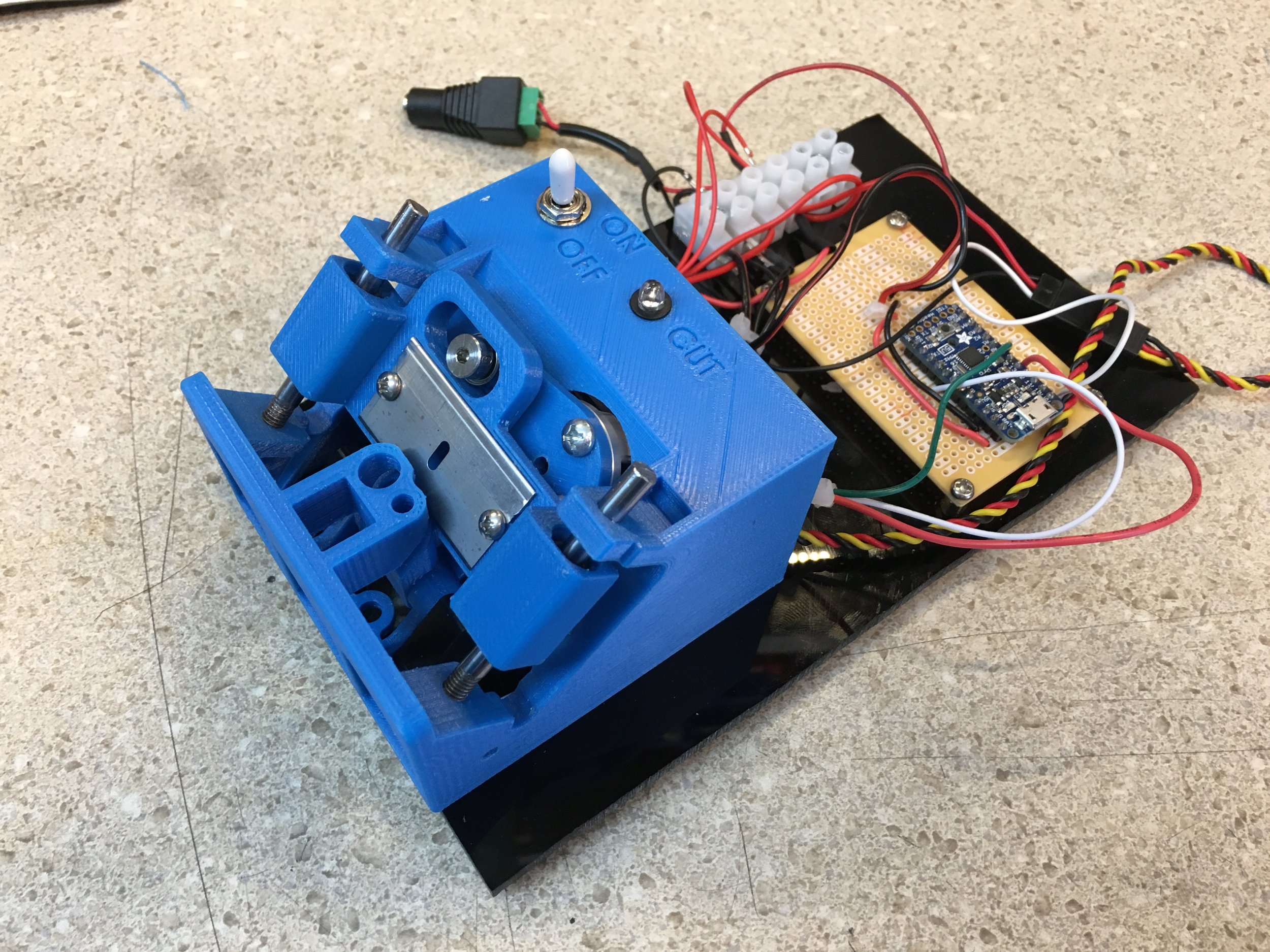

Device Prototype #2: Electromechanical device to automate a repetitive manual operation. The final deliverable was a 3D printed prototype with IR sensing, servo-actuated motion, and a microprocessor-based controls system.

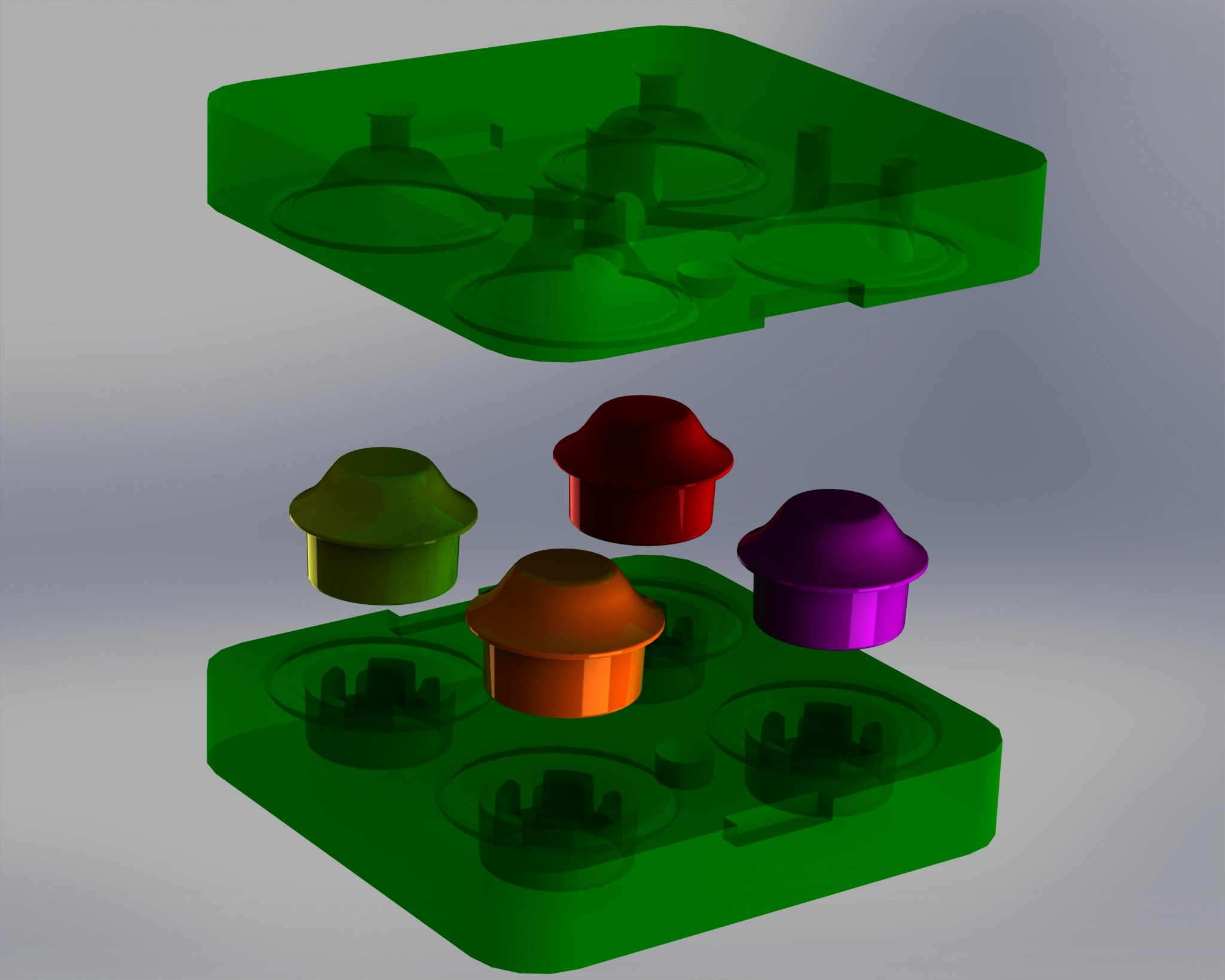

Device Prototype #3: 3D printed molds for an insulating plug. 3D printing and silicone molding enabled rapid iteration of concepts w/ minimal investment, and a clear path to production.

Artistic and Entertainment Projects

Large Scale Public Art: Various projects with San Francisco-based artist Charles Gadeken. Sculptures from this collaboration have been covered in local and national press, featured on This is Colossal, and sold at auction via Sotheby’s. Role: Conceptual design, detailed sheet metal design, fabrication and installation assistance.

Entertainment: Assisted Simone Giertz in production of multiple editions of her “sh!tty robots”, and ruggedized her early prototypes for transport to press appearances. These props have been seen on Wired.com, in TEDx talks, and a Kellogg’s advertising campaign featuring Giertz. Role: Design and fabrication.

Personal Projects

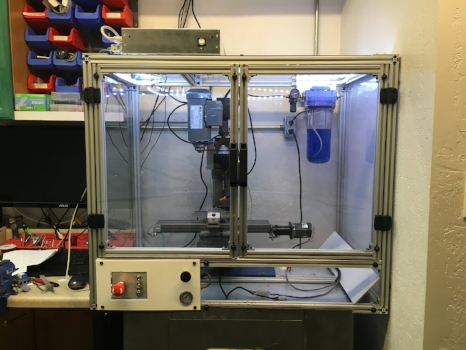

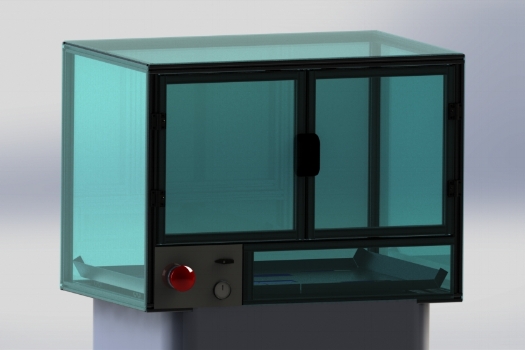

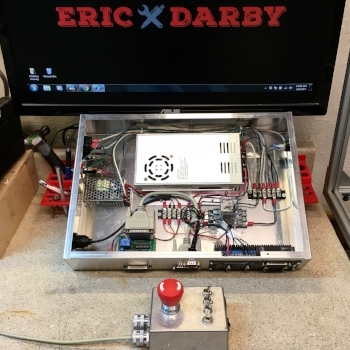

CNC Mill: Darby Prototype’s first purchase was a partially completed Taig CNC milling machine. we rebuilt the controls, designed and built a custom enclosure, and added safety features. This mill was retired as the business grew. Our current shop tool inventory is here.

Toolbox and CNC workstation: Eric purchased this SnapOn toolbox in heavily-used condition, and completed a full restoration, including a custom top hutch with lighting, power outlets, and organization of CNC workholding and fixturing.

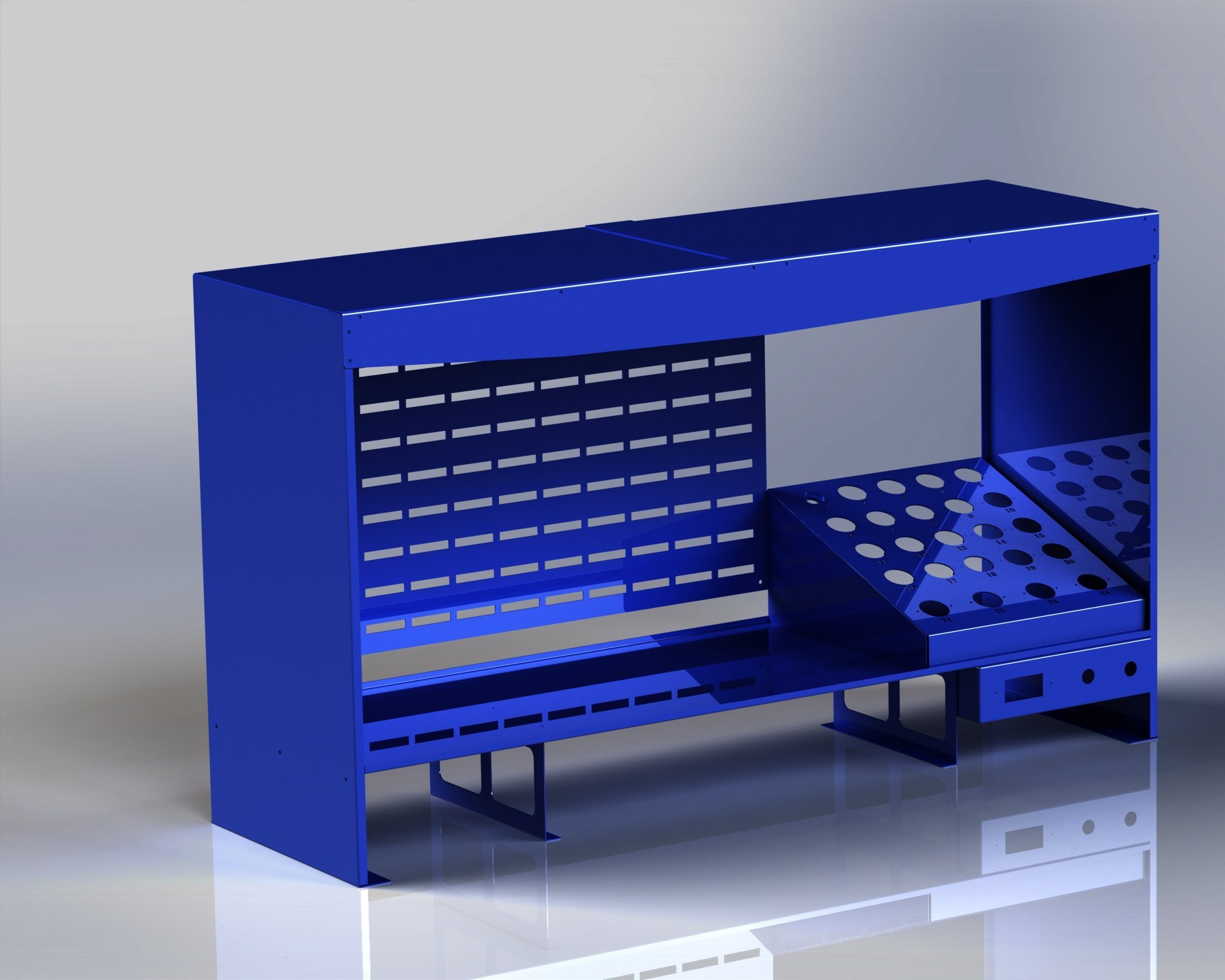

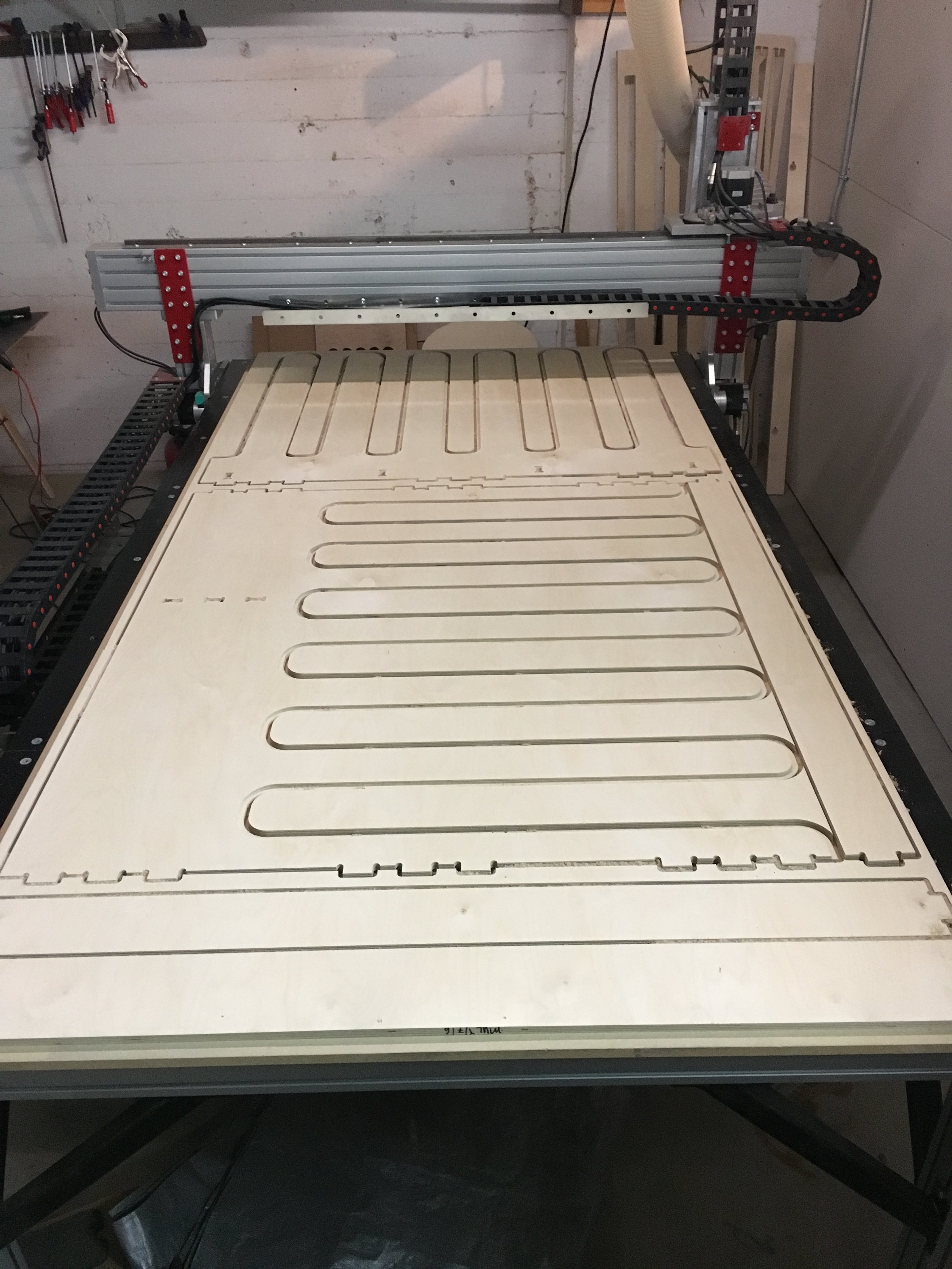

“Weekender” camper conversion: Eric designed an insert with sliding bed platform and pull out kitchen modules, to convert a small delivery van into a compact camper. The build also included interior upholstery and an electrical system with lighting, USB ports, and a 700 watt AC/DC inverter. Parts were designed it in Solidworks, laid out w/ Fusion 360 CAM, and cut with a CNC router.